Factor 55 Takes Part in US Military Battle Exercises

*No Federal Endorsement Intended or Implied*

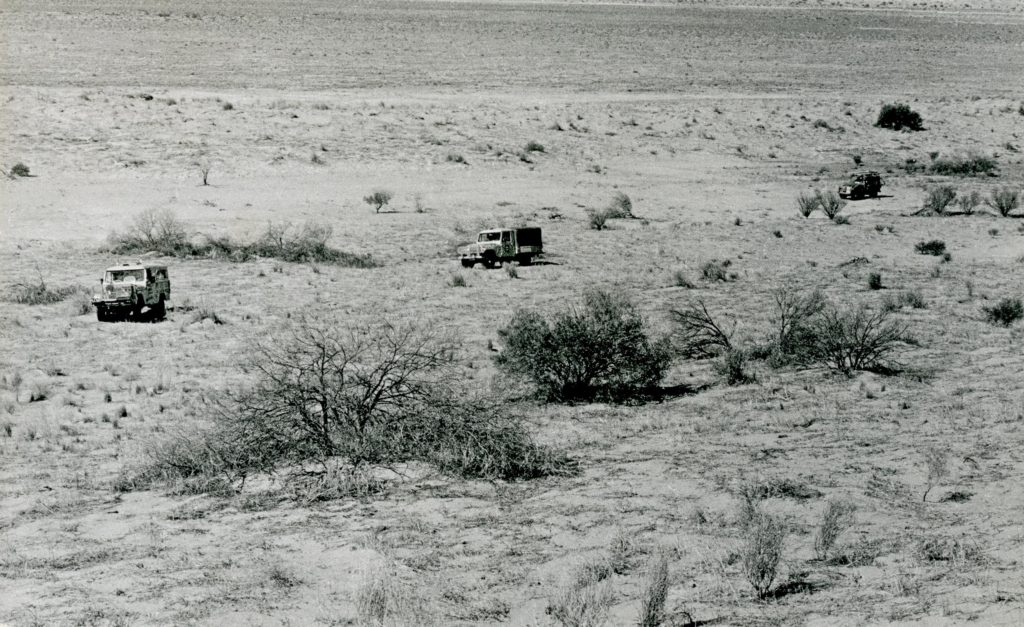

Recently we were honored to take part in some battle exercises. In this training exercise, soldiers were being instructed on Personal Security Detail Recovery. The objective of PSDR is to be able to extract a disabled vehicle quickly and safely without soldiers having to exit either vehicle. These battle conditions include vehicles damaged by IEDs as well as taking on other enemy fire. In the attached photos are examples of how these Humvees are prepared prior to entering hostile territories. Note how vehicle recovery straps are coiled and pre-attached to the front and back of each vehicle. Also note how the ends of the straps are also easily reachable through the Humvee side windows.

As an example, under battle conditions when a Humvee is damaged by an explosive charge and rendered disabled, the next Humvee in line can pull closely along the side of the damaged Humvee, and through the side windows, soldiers can connect the two ends of the straps with a soft shackle or hard shackle, thereby attaching one vehicle to another without any personnel having to exit the vehicle and put any lives in harm’s way. Once the strap ends are securely connected and tension is applied, the tow straps will uncoil and break free from the attach points and the damaged vehicle can be safely towed back to safety. The close side by side vehicle arrangement also reduces the exposure to taking on sniper fire to the soldiers that are positioned adjacent to the open side windows. These exercises are practiced over and over again until the process is second nature. They say that necessity is the mother of invention and in this case USA soldiers came up with an ingenious way to quickly and safely extract a fellow crew in need.

These exercises were being conducted with USA made Factor 55 Standard Duty polyester Tow Straps attached with our Velcro Strap Wraps and linked together using our Standard Duty and Extreme Duty Soft Shackles.

Let’s hope that none of these soldiers will need to perform this type of vehicle recovery. Godspeed

*No Federal Endorsement Intended or Implied*

#F55Equipped #EquippedToExplore

#factor55 #closedsystemwinching #shadebrigade

#precisionengineering #professionalrecovery #itsyourwinchonlysafer

#madeinusa #madeintheusa #buyamerican #winch

#winchsafer #winchsafety #vehiclerecovery #trailridesmatter

#racerecovery #innovationnotimitation #hookreplacement

- Published in Uncategorized

Factor 55 introduces NEW 10 inch Standard Duty Soft Shackle

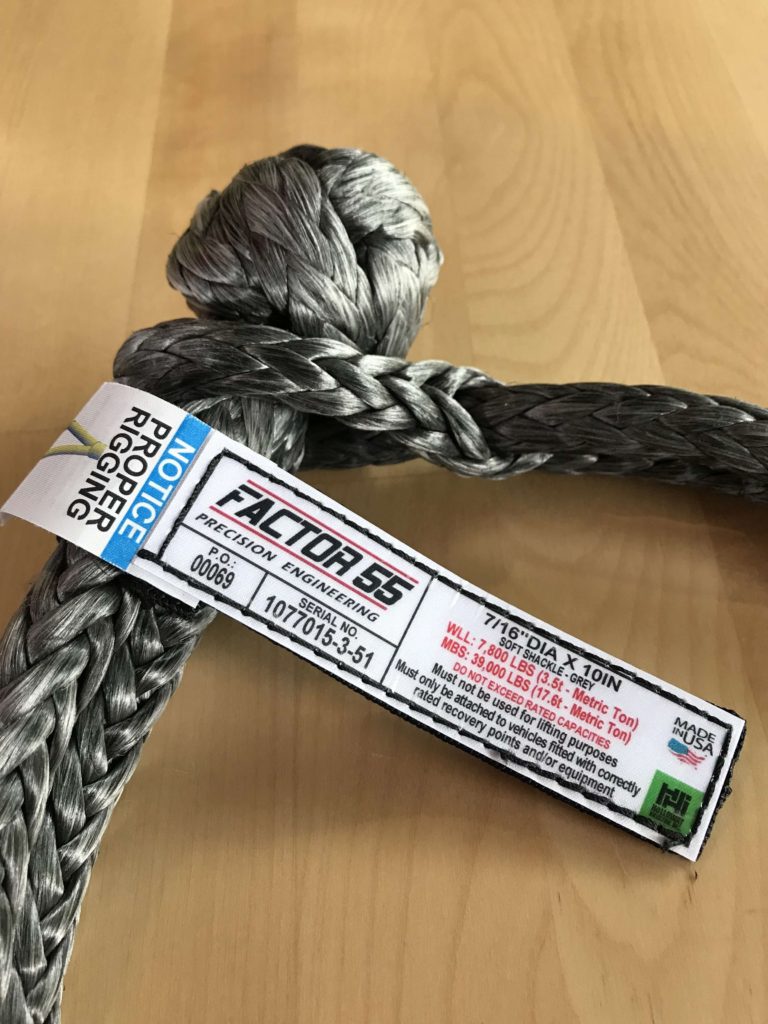

You asked for it and we listened. Factor 55 introduces our new 10 inch Standard Duty Soft Shackle.

The Factor 55 10 inch Standard Duty Soft Shackles are Made in the USA under the uncompromised Factor 55 quality standards. Like all Factor 55 rigging products, these shackles have been lab and field tested to assure consistent repeatable minimum breaking strength values. Each Standard Duty soft shackle is constructed of 7/16 diameter UHMWPE 12 strand rope similar in construction to synthetic winch lines. WLL and minimum breaking strengths clearly marked. Minimum Breaking Strength – 39,000 pounds WLL – 7,800 Pounds. Weight – 6.3 ounces.

Similar to our Extreme Duty Soft Shackles, each individual soft shackle is serialized for manufacturing date and material lot traceability. You can now decide whether you need full outer sheath protection for severe conditions or a less extreme, more affordable option. The Factor 55 10 inch Standard Duty Soft Shackle will be a great addition to any recovery kit.

Engineered, Tested, and Made In The USA

- Published in Uncategorized

Factor 55 to Support BFGoodrich East-West Australia Jeep Expedition

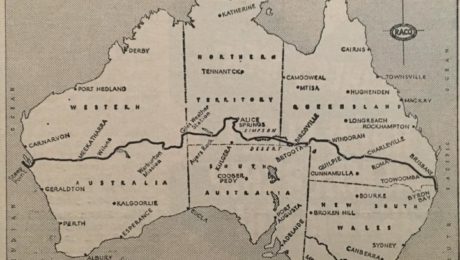

In just a few weeks, Off-Road Motorsports Hall of Fame Inductee and owner of Adventure Architects LLC, Chris Collard will be joined by fellow Hall of Fame Inductee and Jeeping guru Rick Pewe, retracing the tracks of the 1969 Simpson Desert East-West Australia Expedition (the first Jeep crossing of the entire Australian continent).

To celebrate this milestone adventure, Ben Davidson of Seven Slot Expedition, along with Ian McDonald and John Eggleston (two of the three surviving members of the original expedition), Hall of Fame Inductee Sue Mead, and Justin He will head a group of Jeeps from different eras including TJ, JK and new JL Wranglers replicating the 1969 adventure. The crossing will take 20 days +/- and cover 3,000 miles through some of toughest outback terrain. Highlights and challenges for the crew will include the remote tracks and deep, soft, unforgiving sand of the northern Simpson Desert before reaching Alice Springs. From there they will head to Uluru and Kata Tjuta before heading west across Outback WA to reach Steep Point and the Indian Ocean. Crossing 37 degrees of longitude.

We are honored to have been chosen as the supplier of winch safety and vehicle recovery products for this historic adventure. The 50th Anniversary project- BFGoodrich East-West Australia Jeep Expedition – starts in a few weeks and we wish Chris and his entire team a safe and successful journey.

BFGoodrich Tires | Jeep | WARN | Bestop | TeraFlex Suspensions | JeepKonection | Jeep Action Magazine | Jeepfreeks | Offroad Animal

#builtonbfg #km3 #jeep #sevenslotexpedition #warn #teraflex #bestop#jeepkonection #offroad_animal

#factor55 #closedsystemwinching #shadebrigade

#precisionengineering #professionalrecovery #itsyourwinchonlysafer

#madeinusa #madeintheusa #buyamerican #winch

#winchsafer #winchsafety #vehiclerecovery #trailridesmatter

#racerecovery #innovationnotimitation #hookreplacement

#equippedtoexplore

- Published in Uncategorized