The Importance of Material Properties

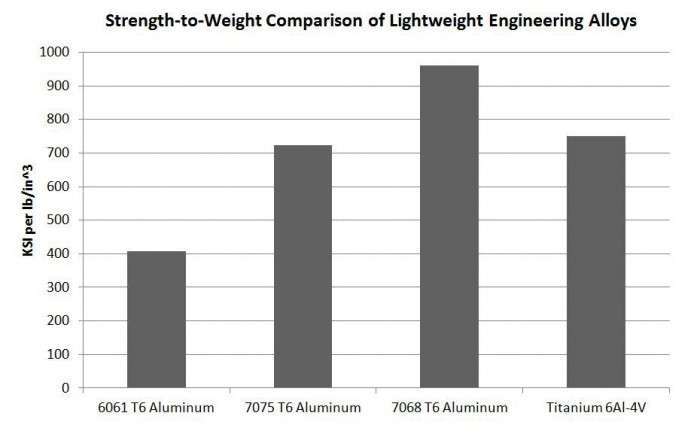

The importance of material properties. When it comes to lightweight alloys for vehicle recovery parts, it’s hard to beat Aluminum and Titanium. High strength, lightweight, ductility, corrosion resistance, and repeatable test performance are all of the qualities to look for.

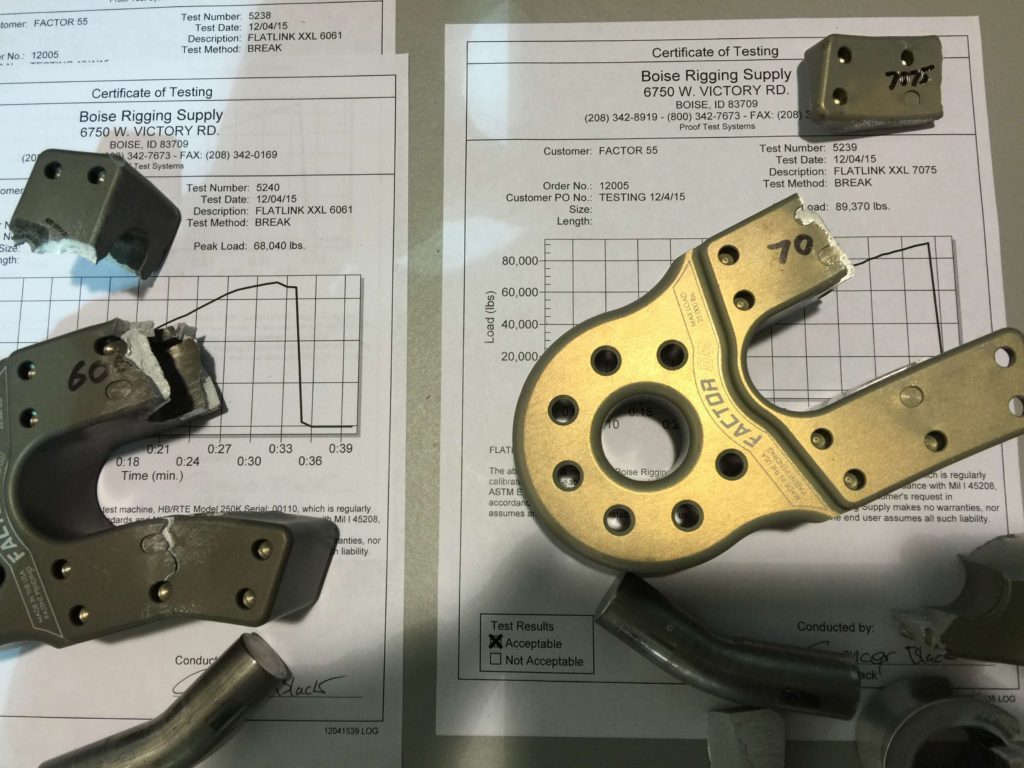

Take a look at the attached chart showing the relative strengths versus weights of aluminum alloys and 6Al-4V titanium. We use 6061 and 7075 Kaiser aluminum alloys along with 6Al-4V titanium alloy for our winch shackle mount products. Of course, 7068 aluminum is the strongest of the aluminum alloys and is popular in the defense industry, but it’s cost-prohibitive in most cases. Instead, we use 7075 and simply add more material in the high-stress areas resulting in an equivalent strength with a bit more weight.

Have a safe and Happy Father’s Day!

Factor 55 – Engineered, Tested, and Made In The USA

- Published in Uncategorized

Commercial and Industrial Recovery Gear

| Did you know that Factor 55 supplies much higher rated hard and soft rigging to our industrial/commercial customers? Soft shackles with a minimum breaking strength of 294,000 pounds, or kinetic ropes with breaking strengths exceeding 200,000 pounds. Similar to our products for the truck and SUV market, each piece of rigging is Made In The USA and marked with individual serial numbers for lot traceability and build date. Each soft rigging unit is also treated with Fiberlock, a Military and Safety industrial polymer. Check out Zac and Justin holding a typical truck/suv product opposite to our industrial line. Factor 55 – Engineered, Tested, and Made In The USA |

- Published in Uncategorized