Broken Winch Line? Splice or Knot tie?

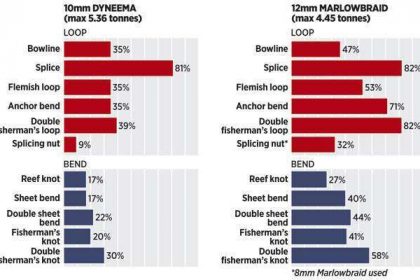

Think tying a knot to repair your broken synthetic winch rope is a good idea? Think again. Different types of knots subject the rope fibers to different levels of bending stresses, with some knots subjecting the rope fibers to severe bending (Bowline knot). HMPE is a slippery fiber and does not lend itself well to knot tying. Look at the chart from Marlow Ropes that displays the percentage of strength reduction resulting from different knot types. The left column represents the common SK75 unsheathed winch rope that most of us off-roaders use, the right is a sheathed rope from Marlow. “BEND” represents the knots that join two ropes, where “LOOP” refers to tying a loop on the end of your rope. You can lose up to 65% of your rope strength from tying the wrong knot (Bowline). Even the best knot (Double Fisherman’s Knot) retains only 39% of the rope strength. What’s the best way to field repair your broken winch rope? Splice it, it’s not that difficult to learn and coming soon it will be even easier.

WARN | I4WDTA – The International 4-Wheel Drive Trainers Association LLC | Barlow Adventures | Off Road Consulting and Driving Instruction |Superwinch | Ultra4 Racing | ULTRA4 EUROPE | Ultra4 Mexico | King of The Hammers | CRAWL Magazine | Overland Journal | Overland Experts (OEX) | JM Rigging Supply | COMEUP | Custom Splice | Southeast Overland | Samson: The Strongest Name in Rope |