Proper Winching Is More Than Pushing A Button

By Kyle Buchter, OFFROAD CONSULTING & DRIVING INSTRUCTION

In my experience after decades in the field, off-roading’s second most assumed skill comes down to one thing—Winching.

You just wrap the line around a tree and push the button. How hard can it be, right? I know there are a lot of off-roaders out there who automatically think they know how to winch their Jeep out of any situation or use it to help others who may be in trouble. I’ve seen it first-hand.

But in reality, there is a lot more that goes into proper, and safe, winching than just hooking it up, doing some guesswork, and pushing the button. Conducting a stuck assessment, utilizing proper gear, understanding the proper load ratings, winch specs, vehicle weights, proper rigging—these are all things that need to go into proper, and safe, winching.

And failure to understand these dynamics can quickly lead to damaged vehicles, damaged equipment, personal harm, or even death. Really, this is not Fake News. Never assume what you do not know when you are out on the trail. Bad things can happen.

Choosing the proper gear or equipment can get a little challenging, and there are some questions you should ask yourself before hitting the add to cart button—another button that will get you into trouble.

So, before you spend your hard-earned money on something that you may never use, ask yourself the following:

- There are so many winch choices out there, which is the best?

- Are you getting the winch for looks or are you going to see trails? There are a lot of sales pitches and products designed just for the sale and not true functionality or performance. (If it looks cool, chances are it probably has the limited off-road ability). Build your vehicle to fit your lifestyle both on and off-road. Get what you can afford and what will meet your needs.

- Do you need the $2000 winch or the $500 one?

- How often are you going to use it and for what purposes?

- What type of vehicle is it going on?

- How are you attaching it?

As you can see, there is a lot that goes into making a proper decision about using a winch. Not just pushing a button.

Oh, and don’t get caught up in all the things others say to justify their winch purchase. Some will argue up and down that their $200 winch will show up all the ‘expensive’ winches any time, any day.

So do your research and talk to those who use their equipment often. Ask around, or research who in your area does professional recoveries, and then spend some time learning what gear they use. They will certainly give you an honest opinion based on their own experience because if that stuff fails, they don’t make money. Also, try and avoid the guys who yanks their friends out of fields during the one time they go off-roading per year. Their stuff may work, but they really do not have the overall expertise to give you an accurate overview.

This theory really goes for any type of recovery gear. Get what you need and make sure everything is rated appropriately.

How do you know what to get, though? And how do you find out what it all is rated? Well, chances are there are winch and recovery classes available somewhere in your area that will give you the opportunity to interact, ask questions and make an educated decision on which gear is best for YOU.

One word of advice, make sure the instructor is certified and/or trained in what he is teaching. Don’t settle for a few guys talking shop at a local Jeep club meeting. They may know what they are talking about, but they may not either. Do you want to wait for a serious trail recovery situation to find out?

One of the biggest things to understand is that performing a stuck assessment needs to happen before you even start using your winch. Don’t spool the line out. Don’t push any buttons.

And all you need to accomplish this assessment is your eyes and common sense. Look at the situation to determine just how badly the vehicle is stuck. If you don’t assess the situation you are just winging it. Winging is for birds and is NOT a valid recovery technique.

Being able to do a proper stuck assessment can set you up for recovery success instead of burning up your equipment—or worse.

There are people who can actually estimate, within a few hundred pounds, how much force it will take to pull a stuck vehicle out of the situation. This is a skill and not an assumed judgment.

Also, have you ever looked at your recovery gear and noticed the load ratings? Well, they are there to keep the user safe and are something you should understand. If not, or they are ignored, then equipment damage and/or death can occur.

If your load is too heavy, or if your equipment is damaged before you even start a recovery, it can quickly lead to failure. So know and understand what you have, and then decide what else you need. Take the time to learn when equipment is safe for use and also understand what to look for when it needs to be replaced.

Additionally, learn what type of gear should be used in what situation? Don’t assume. Just because a vehicle may be ‘stuck’, does not mean it is always winch time. Sometimes simply hooking up a recovery strap, or using traction aids like ActionTrax—even solid spotting— can get a vehicle out of the situation without resorting to a winch.

So, after reading all this important information, and taking everything into consideration, you may decide to install that winch. Or you went ahead and ordered one and the UPS man is delivering it today.And that is fine.

Guess what, though? Your learning doesn’t stop here.

What is its duty cycle? What is it rated at? What is the pull by layers? How many amps are being drawn at what weights? How much rope or cable is on the winch?

These are all important things to understand about your winch, and things that should determine, in your mind, what it can or can’t accomplish before you even hook anything up.

Oh, and did you notice we didn’t mention anything about pressing a button? This next sentence is really important. Winches are not miracle tools. I repeat, winches are not miracle tools. You need to understand what they can—and can’t—do. And yes, even the most expensive, or that $200.00 winch, has limitations. So how about some Winchonometry. Oh and this is NOT the same as Wenchonometry. This recovery tool is a winch, not a wench.

So, say you have a slightly modified JK that weighs 5,000 pounds and also has a 10,000-pound winch on the front. The vehicle is currently stuck in a two-foot-deep mud pit, and you are looking to use the winch to pull yourself out. How long will it take for the train to get to the train station? Wait, wrong question.

You should really ask yourself how much line will you need and what type of rigging setup is best.

This is a lot of work and before you execute, will the winch even pull you out of the situation? Also, where are you hooking this rigging?

These questions are all part of the stuck assessment, and asking them will make you think outside of the box. Vehicle weight is something everyone should be able to figure out, and preferably know BEFORE you find yourself stuck, or attempt to help someone else.

What does the vehicle weigh that is stuck? How much resistance does the vehicle have in its situation? Or, in other words, how stuck it is at the moment? Most have heard of single line pull and double line pull, but what is needed for which situation or some other setup?

Also, are these questions overwhelming? They are not really meant to scare you away, or even to push you away from learning.

As you can see, there is a lot that goes into winching besides, well, hooking up a line and pushing a button. It is a skill you need to learn and take seriously, as well as constantly maintaining with some “continuing education”.

If you are not comfortable answering any of the above questions or are not sure about product or gear specs, then taking a winch class may be best for you. Winch riggings are all different. The vehicle may be off-camber; it could be stuck in mud or uphill. And it will be the creativity and the safe usage of materials that get you through, and out, of the situation.

Damaging a vehicle and/or equipment is not a badge of honor. It is a fault. And no one wants that to happen.

Proper equipment use is key and a willingness to learn is crucial. Efficiency is what you are going for—the capabilities to get the vehicle out safely, with the right setup, on the very first attempt.

Take the time to study and learn the correct ways and correct gear for you and your vehicle. We all want to see everyone come off the trail safely, and with an undamaged vehicle.

Take any ego and assumptions out of the equation.

- Published in Uncategorized

NOW SHIPPING WORLDWIDE

You asked for it and we listened.

The FACTOR 55 website now ships Worldwide.

FACTOR 55 – Engineered, Tested, and Made In The USA

- Published in Uncategorized

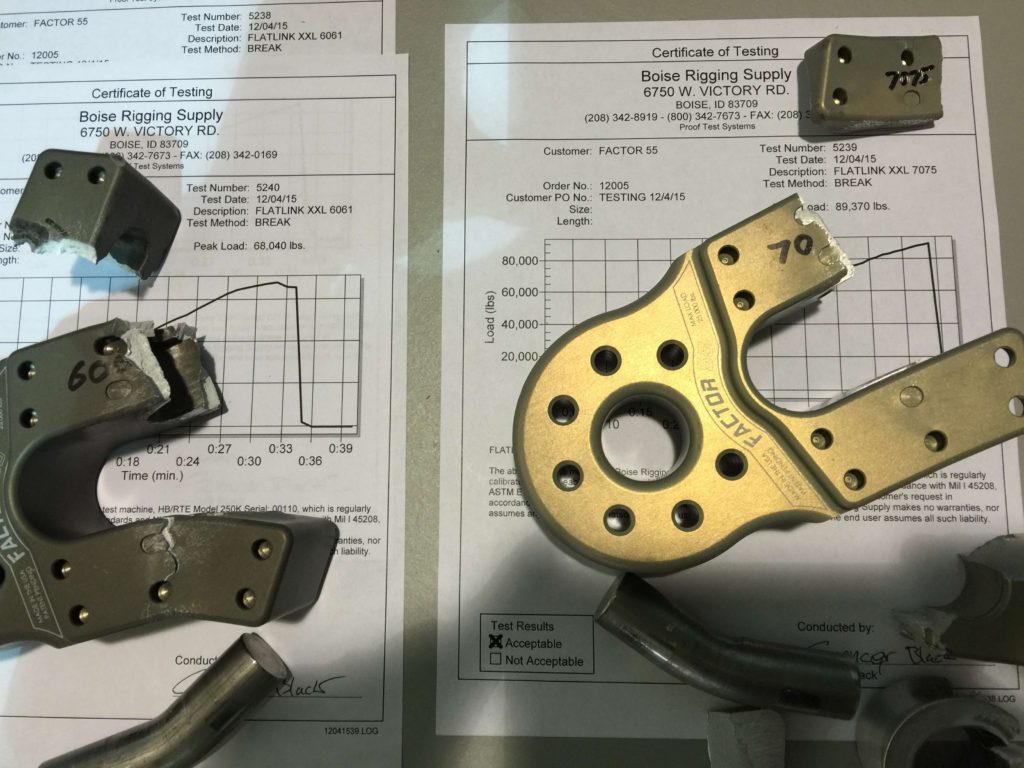

Is laboratory destructive testing of vehicle recovery products important?

Is laboratory destructive testing of vehicle recovery products important?

We think it is and openly share our test results with the public. It’s how we built our highly engineered brand over 9 years ago and we continue this practice today. Although Finite Element Analysis can oftentimes get close to predicting the structural behavior of a product, especially getting close to the ultimate breaking strength, the yield point (plastic deformation – permanent distortion) of materials is a bit harder to predict.

When we test our products, we measure critical dimensions prior to applying loads and remeasure these points after each test load is applied, leading up to the final failure. This way we can observe and measure at what point permanent deformation occurs. Combine this type of lab testing with real-world usage by professionals in various industries, and the result is a consistently performing product for vehicle recoveries. No surprises here, just ultra-strong predictable performance in all Factor 55 rigging products.

Look for additional test videos in the near future as we release several new rigging products in 2021.

Factor 55 – Engineered, Tested, and Made In The USA

- Published in Uncategorized

HOLIDAY CLOSURE NOTICE

As 2020 winds down, we want to express our sincerest gratitude for your continued trust and support of FACTOR 55. We have all endured unprecedented challenges this year but the continued loyalty, kindness, and resilience of our customers have inspired us beyond words.

We will be closed from Thursday, December 24th until Sunday, January 3rd. Any order placed between those dates will begin shipping on January 4th, 2021.

On behalf of our FACTOR 55 family, we wish you a very Merry Christmas and a safe and Happy Holiday season. We look forward to continuing to serve you in 2021!

-FACTOR 55 Staff

- Published in Uncategorized

Interested in Advanced Rigging for Vehicle Recovery?

For those of you that are interested in advanced rigging for vehicle recovery, look no further than your local vehicle recovery trainers. Take a look at the photos sent in by trainer consultants Robert Wohlers of Off-Road Safety Academy – Blue Sky Adventures, Inc. and Kyle Buchter of Off Road Consulting and Driving Instruction. These professionals are always on the search for finding innovative and safer methods to recover stuck vehicles and have found innovative ways to use our Load Distribution Plate product.

One of the photos shows how the LDP can be used to shorten a winch line or winchline extension. We all know that our winch capacities are rated with very little winch line left on the drum. The mechanical advantage of the winch increases as the diameter of the spool of rope decreases. If you don’t have a snatch block and need a bit of additional winch pulling power, you can simply pay out more of the line to reduce the spool diameter. But what if your anchor point is too close to your vehicle and you simply can’t use the additional winch line length? Well then, you will need to shorten the winch line and that’s what is being demonstrated in the image. If this kind of subject matter is of interest to you, let us know and we can share more of these advanced rigging techniques.

Factor 55 – Engineered, Tested, and Made In The USA

#factor55 #closedsystemwinching #equippedtoexplore#shadebrigade#precisionengineering #professionalrecovery #itsyourwinchonlysafer #madeinusa #madeintheusa #buyamerican #winch #winchsafer #winchsafety #vehiclerecovery #trailridesmatter #racerecovery #innovationnotimitation #hookreplacement

- Published in Uncategorized

NEW Product UTV/ATV Extreme Duty Kinetic Energy Rope 5/8″ x 20′

NEW PRODUCT ANNOUNCEMENT- Factor 55’s 5/8″ x 20′ Extreme Duty Kinetic Energy Rope rope is coated with a flexible, durable, weather-resistant polymeric coating. Rubberized rope eyes further increase durability at the wear points of the rope. Rated at 14,800 lb MBS, Factor 55’s 5/8″ x 20′ diameter Extreme Duty Kinetic Energy Rope is designed for use on increasingly popular UTV/ATV/POWERSPORTS machines. While smaller than some of the other Kinetic Ropes Factor 55 offers, the 5/8″ x 20′ rope still packs a lot of performance in a compact package.

Factor 55 | Engineered, Tested, and Made In The USA.

SPECIFICATIONS

– For use on UTV/ATV/POWERSPORTS

– 5/8″ x 20′ Length

– 14,800 lb Minimum Breaking Strength

– Double Braid Nylon Construction

– Polymeric Coating for Abrasion Resistance

– Sealed Against Stain and Water Absorption

– UV and Abrasion Resistant Coating

– Individually Serialized for Material Lot Traceability

– Weight 2 lbs 10 oz- Made in USA

Want to improve your recovery techniques? Be sure to pick up a copy of our Basic Guide to Kinetic Energy Recovery & Towing a Disabled Vehicle Off-Road Manual co-authored by Off-Road Safety Academy – Blue Sky Adventures, Inc.

Education is your biggest asset.

- Published in Uncategorized

HAPPY 4th of JULY

Our offices will be closed Friday, July 3rd, in observance of the 4th of July Holiday.

Normal business hours will resume on Monday, July 6th.

We wish you and yours a happy and safe Independence Day!

From all of us at,

Factor 55

Engineered, Tested, and Made In The USA

- Published in Uncategorized

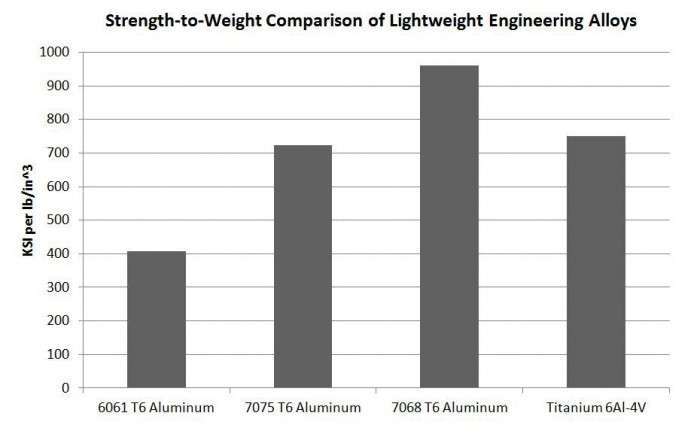

The Importance of Material Properties

The importance of material properties. When it comes to lightweight alloys for vehicle recovery parts, it’s hard to beat Aluminum and Titanium. High strength, lightweight, ductility, corrosion resistance, and repeatable test performance are all of the qualities to look for.

Take a look at the attached chart showing the relative strengths versus weights of aluminum alloys and 6Al-4V titanium. We use 6061 and 7075 Kaiser aluminum alloys along with 6Al-4V titanium alloy for our winch shackle mount products. Of course, 7068 aluminum is the strongest of the aluminum alloys and is popular in the defense industry, but it’s cost-prohibitive in most cases. Instead, we use 7075 and simply add more material in the high-stress areas resulting in an equivalent strength with a bit more weight.

Have a safe and Happy Father’s Day!

Factor 55 – Engineered, Tested, and Made In The USA

- Published in Uncategorized

Commercial and Industrial Recovery Gear

| Did you know that Factor 55 supplies much higher rated hard and soft rigging to our industrial/commercial customers? Soft shackles with a minimum breaking strength of 294,000 pounds, or kinetic ropes with breaking strengths exceeding 200,000 pounds. Similar to our products for the truck and SUV market, each piece of rigging is Made In The USA and marked with individual serial numbers for lot traceability and build date. Each soft rigging unit is also treated with Fiberlock, a Military and Safety industrial polymer. Check out Zac and Justin holding a typical truck/suv product opposite to our industrial line. Factor 55 – Engineered, Tested, and Made In The USA |

- Published in Uncategorized

Customize Your Rope Guard

We have received many requests about the ability to customize the Rope Guards on our line of foldable winch line shackle mounts like The FlatLink, FlatLink E, UltraHook, etc.

Watch the video from our friend @im_just_jon_ and @mt_t4r , shot and edited by @basicbrando , to see just how easy it is to customize your Rope Guard! Every Rope Guard comes with an additional sticker inside the instructions. This will allow you to custom finish your Rope Guard and still maintain an OEM look.

Have a custom color on your build? This is the perfect way to accent it.

As we go into the long Memorial Weekend let us not forget the reason. Honor all those heroes who have paid the ultimate price for our safety and freedom. All gave some, some gave all. 🇺🇸

Thank you to all those who have served past and present.

Factor 55- Engineered, Tested and Made in USA

・・・

#factor55 #closedsystemwinching #equippedtoexplore#shadebrigade#precisionengineering #professionalrecovery #itsyourwinchonlysafer #madeinusa #madeintheusa #buyamerican #winch #winchsafer #winchsafety #vehiclerecovery #trailridesmatter #racerecovery #innovationnotimitation #hookreplacement EQUIPPED TO EXPLORE™ Closed System Winching™

- Published in Uncategorized