Holiday Closure 12-25 thru 1-1-18

- Published in Uncategorized

UV Degradation of Synthetic Winch Rope

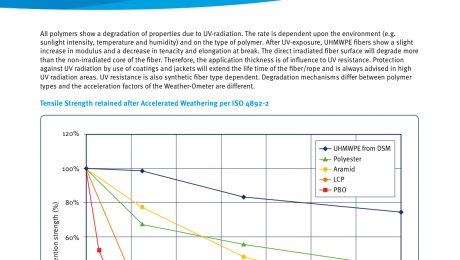

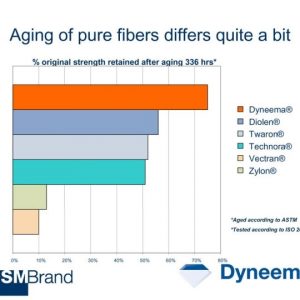

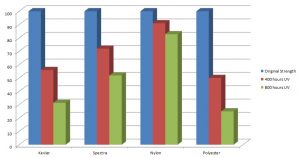

You asked for it and we listened. Many of you wanted more information on the UV degradation of synthetic winch rope. For off-roaders, UV damage to winch ropes is secondary to the more damaging abrasion and impacts we subject our lines to. But with regard to UV damage, the web is full of anecdotal information about this subject, but what are the real facts? Many will claim that winch ropes are coated with UV inhibitors that prevent ropes from getting UV damaged, others say that all polymers are subject to some level of UV damage. Since we don’t have the facilities to conduct an accelerated UV exposure test ourselves, we turned to our friends in the cordage industry as well as scoured the web for any real test data. Here is what we have discovered. You can extrapolate the data as you wish.

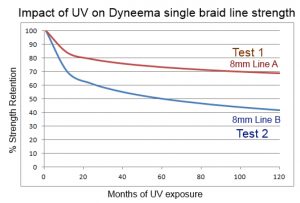

First of all, a majority of the winch rope manufacturers do not manufacture the individual UHMWPE fibers that ropes are comprised of. These rope companies purchase spools of the fibers/yarns from companies like DSM which owns the Dyneema trademark. The real fiber knowledge resides with these fiber companies. In the images below we have included UV test results direct from the fiber source – DSM. We have also included data from the sailing (coated and uncoated fiber) and the climbing industry.

As the exposed outer layer of your rope sustains UV damage, the damaged fibers become opaque which attenuates further damage to the inner rope fibers. The problem is that the UV damaged outer rope layer is weaker and abrades and rubs off easier when used, exposing fresh undamaged fibers beneath. This is not as much a problem with a static application like standing rigging in sailing. However, this can be a problem in a dynamic application like off-road winching where we are repeatedly rubbing and abrading the dirty gritty winch lines across our fairleads.

So how do we tell how much strength our winch ropes have lost due to UV damage? You can’t. So what’s the take away then? All fiber and rope companies agree that prolonged UV exposure will damage UHMWPE fibers to some extent. In some cases up to a 20% strength reduction can occur in under a year. Take a look at the UV data charts and decide for yourself. The simple fix is to cover your winch line from the sun. Winch covers work well to cover the spool, and because silicone is inorganic, an opaque RTV silicone can be used to cover smaller areas of winch line as well. Common Cordura abrasion guards can also protect the last portion of your line from UV damage, but don’t rely on these guards for winch line protection when rock crawling.

#factor55 #closedsystemwinching

#shadebrigade

#precisionengineering #professionalrecovery #itsyourwinchonlysafer#madeinusa #madeintheusa

#buyamerican #winch #winchsafer#winchsafety #vehiclerecovery

#trailridesmatter #racerecovery #innovationnotimitation

WARN | CRAWL Magazine | SpiderWebShade | Carolina Metal Masters |TNT Customs | sPOD | Rock Krawler Suspension | BFGoodrich Tires |Raceline Wheels | Radflo Shocks | Savvy Off Road | Synergy Manufacturing| Off-Road Solutions | 4WD Toyota Owner Magazine | Overland Journal |Expedition Portal | Barlow Adventures | I4WDTA – The International 4-Wheel Drive Trainers Association LLC | Ultra4 Racing | ULTRA4 EUROPE | King of The Hammers | COMEUP | Mile Marker Winch | Superwinch | 4×4 Magazine| XTREME4x4MAGAZINE | Jp Magazine | Extreme 4×4 Nation | Tread Magazine | Jeepfreeks | Modern Jeeper | Poly Performance | Safe-Xtract |Bill Burke’s 4-Wheeling America – since 1986 | Overland Experts (OEX) |Master-Pull Recovery Gear | Overland Expo | Scully Offroad | Treaty Oak Offroad | 7P International | JM Rigging Supply | Custom Splice | Southeast Overland | 36 Hours of Uwharrie | Northeast Offroad Adventures Inc. | Four Wheeler Magazine | Bigfoot Winch Ropes | UTV Guide | UTV Sports Magazine

- Published in Uncategorized

Rope Guards for UltraHook and FlatLink Products

We like what we see, but we really like what we don’t see even better ……exposed synthetic winch rope.

Let’s face it, if any of your synthetic winch rope is visible on the front of your rig, then it’s also vulnerable to damage from the sun and impact or abrasion. No one ever argues this point.

If you can see it, then you can ruin it, plain and simple. So where is the best place to stow the end of your synthetic winch line? There is only one place, behind your fairlead where the sun and rocks can’t get to it. Our ProLink family of products have always provided this type of complete rope end protection, and now our Rope Guard equipped Flatlink family of products does the same.

We also make the Rope Guard for the UltraHook product, making the UltraHook the industry’s first winch hook with rubber pads and complete rope end protection. In addition, we also manufacture the industry’s first splice on rope thimble shackle mounts that provide complete rope end protection.

So, if you are running synthetic winch rope and you can see it, then get it out of harm’s way and behind the fairlead where it belongs.

Engineered, Tested, and Made In The USA

#factor55#closedsystemwinching #shadebrigade

#precisionengineering#professionalrecovery#itsyourwinchonlysafer

#madeinusa#madeintheusa#buyamerican#winch#winchsafer#winchsafety

#vehiclerecovery#trailridesmatter#racerecovery#innovationnotimitation

WARN | CRAWL Magazine | SpiderWebShade | Carolina Metal Masters| TNT Customs | sPOD | Rock Krawler Suspension | BFGoodrich Tires | Raceline Wheels | Radflo Shocks | Savvy Off Road | Synergy Manufacturing | Off-Road Solutions | 4WD Toyota Owner Magazine | Overland Journal | Expedition Portal | Barlow Adventures | I4WDTA – The International 4-Wheel Drive Trainers Association LLC | Ultra4 Racing | ULTRA4 EUROPE | King of The Hammers | COMEUP | Mile Marker Winch | Superwinch | 4×4 Magazine | XTREME4x4MAGAZINE | Jp Magazine | Extreme 4×4 Nation | Tread Magazine | Jeepfreeks | Modern Jeeper | Poly Performance | Safe-Xtract

- Published in Uncategorized

FlatLink Rope Guard Installation Video

Our new Rope Guard products come with installation instructions but many of you asked for an installation video as well. Well here it is. Please remember to remove the FlatLink and UltraHook products from your winch cables so that you can properly place them on a horizontal surface for easy drive rivet installation. Have a great weekend everyone! #justthefacts

CHECK OUT THE NEW PRODUCT HERE:

- Published in Uncategorized

Terryadyne Armored Vehicles Chooses Factor 55 LLC for Winch Safety Solutions

- Published in Uncategorized

Closed July 3-4, 2017

|

- Published in Uncategorized

Factor 55 Load Spools and Why We Use Them

Several of you have recently inquired about the function of the load centering spool that comes as standard equipment on our FlatLink XXL product. The spool is not intended to be used as a pulley since there is no type of bearing in the spool. The spool provides a self-centering feature for cables and ropes that are considerably smaller than the cable opening in the FlatLink. We shot a quick video that hopefully answers most of your questions.

#factor55 #closedsystemwinching #madeinUSA

- Published in Uncategorized

Ductility, what is it, and why is it important to off road rigging?

Ductility is a material property that describes a material’s ability to permanently deform or stretch prior to fracture. The more ductility, the more the material can permanently stretch prior to breaking. This is extremely important for winch and offroad rigging because as users, we want to be visually

warned if we are overstressing a piece of rigging hardware.

As you know, during the destructive testing of our own products, we also subject the attached rigging hardware to the same high loads and are never surprised by any unpredictable hardware behavior. Where do you find this type of certified rigging hardware? Unfortunately, not at your local 4×4 shop. On the contrary, your local 4×4 shop is stocked with mostly rebranded cheap imported rigging hardware like hooks and shackles. These poor quality hardware pieces have unpredictable ductility and strength properties.

As you know, during the destructive testing of our own products, we also subject the attached rigging hardware to the same high loads and are never surprised by any unpredictable hardware behavior. Where do you find this type of certified rigging hardware? Unfortunately, not at your local 4×4 shop. On the contrary, your local 4×4 shop is stocked with mostly rebranded cheap imported rigging hardware like hooks and shackles. These poor quality hardware pieces have unpredictable ductility and strength properties.

- Published in Uncategorized

Factor 55 Sponsors Race Vehicle Tech Inspection Tent for 2017 King of the Hammers

Factor 55, the internationally recognized leader in Closed System Winching™ & Recovery, is proud to announce they will be the sponsor of the Race Vehicle Tech Inspection Tent for the 2017 King of the Hammers race. Nearly 500 race teams will pass through this tent to undergo race scrutineering and have GPS tracking units installed. Billed as the toughest one day race on the planet, King of the Hammers will test these vehicles and their drivers to the breaking point. The Factor 55 Vehicle Tech Inspection Tent crew will ensure the teams begin the race in a vehicle that is within the Ultra4 rules and is as safe as possible.

Safety is at the core of what Factor 55 does. Manufacturing the world’s best recovery equipment helps provide racers and consumers alike the best opportunity for a safe offroad experience. When asked about their involvement, Factor 55 President and founder Mike Costa said, “We love the King of the Hammers. No one is harder on our equipment than the teams out here on the lake bed. We felt that sponsoring the Tech Tent was a great way for us to be more involved with the entire community and support Ultra4 racing.”

The Factor 55 Tech Tent is located next to the Factor 55 booth on Warn Way in Hammertown, USA. Tech inspection opens on Friday February 3rd, 2017 and will continue through the duration of the week leading up to the King of the Hammers race on Friday February 10th, 2017. The inspection includes the race vehicle as well as the equipment used by the driver and co-driver including seat belts, helmets, neck restraints and firesuits. In addition to the tech inspection, every race team will stop for installation of their YellowBrick GPS units prior to competing. The YellowBrick is a new requirement for this year’s race. They allow the cars to be followed by race officials as well as providing emergency personnel their exact location on the course.

Factor 55 is very excited to support Ultra4 Racing and its teams and drivers. Please stop by the Factor 55 Booth and Factor 55 Tech Tent to find out more. There’s guaranteed to be plenty of action in Hammertown this year.

- Published in Uncategorized

Destructive Testing

Many of you have inquired about our destructive testing session from last week. Our product development process includes the testing of several design prototypes and small design iterations before we release a product to the public. One of our test challenges is to devise a method to attach to our products so that we can pull a load that does not break the attachment hardware and allows us to gather the Factor 55 product data instead. We prefer to use USA Crosby shackles and in some cases, the ultra strong shackles made by Skookum (9 ton WLL on a ¾ shackle – 5X Safety). In other cases where our FEA results have predicted breaking strengths of less than 30,000 pounds, we can use soft shackles like the ones from Bubba Rope. The pic below shows the type of hardware we need to gather prior to the test session. So what did we test last week?

1) Material yield and breaking test of the Rev. B UltraHook XTV (Hook Opening)

2) Material yield and breaking test of the Rev. B Ultrahook XTV (Closed System Shackle Pin Mount)

3) Material yield and breaking test of the Rev. B ProLink Expert

4) (22”) 3/8 Dyneema long bury splice soft eye – taper against blunt end test (No lock stitching)

5) (22”) 3/8 Dyneema long bury splice soft eye – tapered at both ends (No lock stitching)

6) 3/8 Dyneema knot test – Simple overhand loop knot

7) 3/8 Dyneema knot test – Bowline

Note that proof load yield testing can be in increments as low as 3000 pounds, so an enormous amount of test data is generated from these pull tests. We simply want to disseminate and summarize the data in the most useful form for you guys. Look for this test data and videos in the coming weeks. Designed, Engineered and Made in the USA.

Samson: The Strongest Name in Rope | WARN | Marlow Ropes | Superwinch | Interesting Engineering | Boise Rigging Supply | COMEUP | Northridge4x4 | Quadratec | Morris 4×4 Center | 4 Wheel Parts | CRAWL Magazine | 4-Wheel & Off-Road Magazine | 4Wheel Drive & Sport Utility Magazine | Alloy+Grit – North America’s Land Rover Magazine | Tread Magazine | Mechanical Engineering |

- Published in Uncategorized