- Home

- Products

- Patents and Trademarks

- Closed System Winching®

- FAQs

- Tech Info

- About

MILITARY

INDUSTRIAL

MOTORSPORTS

PUBLIC SAFETY

Phone: (208) 639-1674

Email: sales@factor55.com

Factor 55

107 E 46th St, Unit 108

Garden City, ID 83714

Hook or Screw Pin Shackle - Which is better?

Smart off roaders have known for years that the most secure way to use your recovery winch is replace the hook with a common screw pin shackle. Unless you are competing, the added seconds required to use a shackle versus a hook during a vehicle recovery is not worth the safety risk associated with standard winch hooks.

What is wrong with the hook?

The technical name for a standard winch hook is " Clevis Slip Hook". This describes two things. First, clevis refers to the method of cable attachment - the cable eye is attached to the hook by a clevis pin and cotter pin. Second, "slip" refers to the size of the chain link that can be slipped through the hook opening. Most winches are equipped with 3/8 clevis slip hooks. This means that the hook is designed specifically to work with chains that have 3/8 thick chain links. Unless you are using chains in your recovery, this is not the right piece of hardware to have on the end of your winch cable. At Factor 55 we are still puzzled as to why winch manufacturers continue to sell winches equipped with hooks designed for chain links when off roaders have been using synthetic recovery straps for over two decades now.

In addition, most 3/8 clevis slip hooks have a safe working load limit of 4000-7000 pounds. The average 8K winch exceeds the working load limit of these weak hooks regularly. Of course the safety factor built into the hook is 3-4X, but it is still not wise to exceed any working load limit of any hardware. In contrary, the standard ¾ screw pin shackle has a working load limit (WLL) of 9500 pounds, and a safety factor of 5-6X. Most screw pin shackles have an ultimate breaking strength of 50,000 to 60,000 pounds.

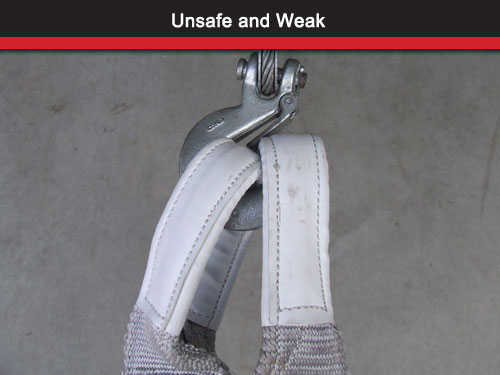

The cross section of the standard hook is airfoil shaped to prevent chain links from slipping, and not ideal for synthetic strap fibers. This shape causes high fiber stresses that reduce the rating of the recovery strap. Hooks equipped with safety latches pose other hazards as well. Many safety latches are simply bent sheet metal parts with sharp edges and springs. This is not a concern with chains, but a potential cutting hazard for recovery straps. The safety latches cannot bear any loads as well.

The hook opening of the standard winch hook is too small to safely attach two ends of a common recovery strap so most off roaders use a screw pin shackle to hold the strap anyways.

Standard winch hooks do not stow neatly against either Hawse or roller fairleads. They were not designed to do this. That is why it is common to see winch cables extended and hooks attached to bumpers, tow hooks, undercarriage parts etc.. It is not recommended to leave the winch cable or synthetic rope pulling at a right angle to your fairlead simply to attach the hook to something convenient – this can permanently weaken the fibers right at the fairlead surface.

Anytime a hook is used, there is a chance that whatever you put into the hook opening can escape. This is especially important in vehicle recovery where the winch cable is cycling in a loaded and unloaded condition regularly as the towing vehicle or towed vehicle lurches forward. In contrary, the standard screw pin shackle is a completely contained link where strap ends have no way of escaping even during tight/loose cycles.

Screw Pin Shackle Benefits:

- Stronger

- Safer - secure link - no chance of strap ends escaping

- Less stress on recovery strap fibers

- Larger opening accepts both ends of a recovery strap

- No sharp edges to cut recovery straps

- Affordable pricing for a superior piece of hardware