TBT | Tie a knot or Splice the line?

Throw Back Thursday

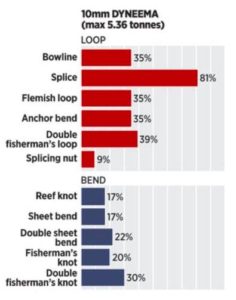

Since a lucky few of you during the holidays may be receiving a new winch equipped with synthetic winch rope, or maybe you are just switching over to synthetic winch rope for safety, it seems like a good time to remind you of the proper way to trail repair a broken winch line. Remember, it’s not “if” a winch line will break, but “when”. Like any polymer fiber, a synthetic winch line is vulnerable to failure from abrasion, sharp edge contact, and shock loading. When it breaks on the trail and you still need a functional loop on the end, it’s natural to want to tie a loop into the end of the line – don’t. Any type of knot tied into HMPE fibered lines will reduce the rope strength by 50% or greater.

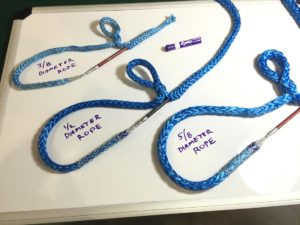

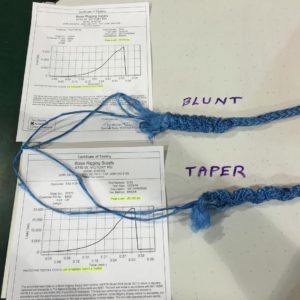

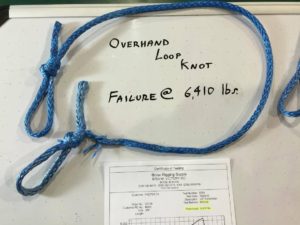

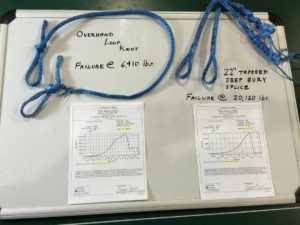

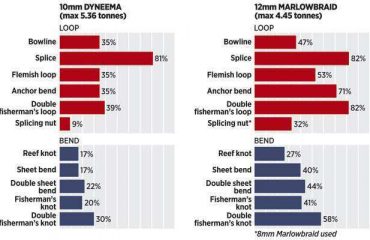

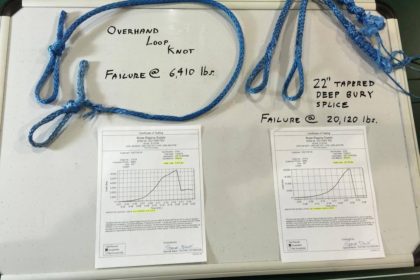

Take a look at the attached images and note the different knot configurations in the chart and the relative strength retained (Marlow Ropes). Even in our own knot (Common Overhand Loop Knot) testing, we could never achieve even 50% of the rope strength. A properly spliced 3/8 rope broke at 20,120 pounds, the knotted version – a mere 6,410 pounds! Do yourself a favor and learn how to properly splice your winch line. It’s easy to learn with all of the youtube tutorials available out there. Our favorite quick repair is the simple deep bury splice. If you are pressed for time, don’t worry about properly tapering the end of the line. We tested a blunt bury against a properly tapered bury and observed only a 10% decrease in splice strength (See chart). Although we prefer using our Fast Fid tool, you can also easily resplice your winch line with a ballpoint pen and some tape. Also, if you are ever at a show we are attending, stop by our booth and we can demonstrate how to perform a deep bury splice in under 60 seconds.

Factor 55 – Engineered, Tested, and Made In The USA